Gym Fitness First Factory boasts state-of-the-art manufacturing facilities equipped with advanced machinery and technology, ensuring the production of high-quality fitness equipment

We understand that one size does not fit all. Our team of skilled engineers and designers can customize fitness equipment to meet your specific requirements and branding needs.

Quality is the cornerstone of our manufacturing process. Every piece of equipment undergoes rigorous quality checks to ensure safety, performance, and longevity.

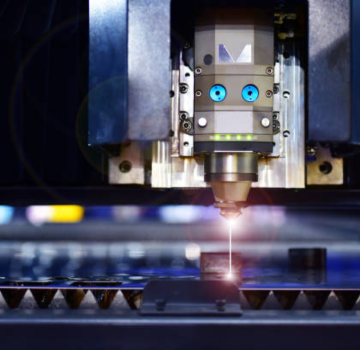

Tube and Plate Laser Cutting Machine helps to produce consistent quality and high precision products.

The CNC pipe-bending machine with German technology ensures accurate arc and angle in bending to achieve perfect biomechanics and anatomically perfect equipment.

CNC machined parts in the equipment, with statistical process control ensure that the fit and functionality of all the parts is perfect.

Usage of jigs, fixtures, tooling to accurately manufacture and assemble machined parts thus resulting in consistent quality products.

Equipment is built as per design and passes through detailed quality checks to ensure that it is within the specifications.

GMAW (gas metal arc welding) set-up used in manufacturing, results in strong, defect-free, and aesthetically appealing joints.

Shot-blasting machine for pre-treatment ensures that the structure is completely free of rust and dirt for optimum adhesion of the powder.

Fully Conveyorized Electrostatic 3-layer powder coating plant with technology from the UK ensures aesthetically appealing and durable equipment.

Our Just-in-Time principles of manufacturing, visual management and Kanban ensure smooth operations and 24X7 availability of spare parts

The high-density rebounded foam is double-stitched with high-quality rexine to make sure that the equipment seats last long.

Thorough Pre-Dispatch Inspection for visual quality and biomechanics before packaging and dispatch, verify that the customers get excellent quality.

Finally, after all the inspection and quality check, the parts are packed into boxes and the material is made ready for dispatch